ITA calibration laboratory

We are accredited by the PCA.

Laboratorium wzorcujące ITA - wersja angielska

Laboratorium wzorcujące ITA - wersja angielska

We individually analyse each enquiry from a technical point of view in order to meet the most demanding needs of our Customers, as far as possible.

In case of positive verification, we will provide you with an attractive price and time offer for the calibration of your instrument.

Once your order has been received, we will start to process it. At this stage, you can expect us to contact you to arrange the most convenient calibration date.

Calibration is performed in accordance with the scope of accreditation, both at the place of work of the device and in our laboratory in Skórzewo.

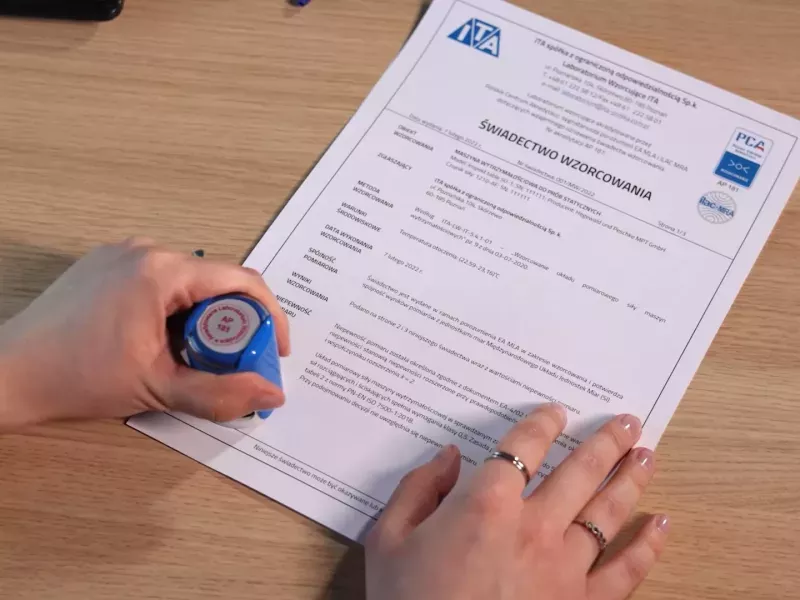

The result of the completed service is a Calibration Certificate signed with the logo of PCA and ILAC MRA. For the sake of the environment and your convenience, we issue this document in electronic form.

Eight years ago, we realised our ambition by setting up an accredited ITA calibration laboratory. Since then, we have not only expanded the range of services we provide, but above all, we have strengthened our position as a reliable partner for Polish industry, in particular for the automotive, aerospace and machinery sectors.

Thanks to ISO 17025 accreditation, our customers can count on the highest quality of calibration services, which makes it easier to pass audits, especially those carried out by external certification bodies. The laboratory has also become an important competence development centre for our team - we are constantly raising metrological awareness and improving internal quality processes.

Our laboratory is distinguished by the calibration within the scope of its accreditation of a wide range of advanced measuring equipment. Since obtaining accreditation, we have been systematically extending the scope of our laboratory's accreditation year by year, constantly adjusting our offer to the changing needs of the market.

We were the first in Poland to obtain the possibility of calibration of optical machines for measuring rotary-symmetrical elements, devices for measuring the outline of a shape, conturographs and Shore hardness meters on the AO, AM, O, OO,OOO,B,C,E, DO,M scale. What's more, our calibration offering includes both on-site and direct-to-customer services, eliminating the need to send equipment abroad and generating real savings for companies.

After eight years in business, we are still dynamically developing the laboratory, investing in modern technology and expanding the scope of calibration. Our goal is to provide the highest standard of metrology for Polish industry and further strengthen our position as a leader in the industry.

We invite you to cooperate with us and use the services of our ITA accredited calibration laboratory!

The frequency of calibration is determined by the user based on the mode of operation and quality requirements. A 12-month cycle is most typical. When determining the calibration interval, the specific characteristics of the device, its intensity of use and its role in ensuring the appropriate level of quality should be considered.

Yes. The ITA Calibration Laboratory is accredited by the PCA, Certificate AP181.

Accreditation of a calibration laboratory means that calibrations are performed under controlled conditions and provide reliable results while maintaining consistency with the units of measurement of the International System of Units (SI).

Depending on the type of device and scope of accreditation, calibration is performed in the ITA laboratory and at the customer's premises.

A certificate with an accreditation mark means that the calibration results are reliable and that the calibration process and all laboratory activities have been confirmed by an accreditation body as compliant with the PN-EN ISO 17025:2018-02 standard. Certificates with an accreditation symbol are treated as certificates ensuring measurement consistency.

We issue certificates in electronic form as PDF files as standard. We issue paper versions at the customer's request. All certificates are stored by us for a period of 5 years. The electronic version we prefer is environmentally friendly, fast and allows customers to resend the certificate if it is lost.

Yes. ITA has specialists in the field of measuring device servicing. If the device requires adjustment, we can perform it before calibration. In practice: first, we determine the scope of service work, and then we perform calibration to confirm the parameters after adjustment.

Zakres akredytacji

Certyfikat ITA